Galvanised Lintels

Compliance & Quality Remain Our Top Priority

choose Complete

Galvanised Lintels

Galintel® is Australia’s leading designer and manufacturer of high quality steel lintel bars for the building and construction industry.

Galintel® works extensively with industry stakeholders on the development and compliance of lintel products to meet Australian building needs and are approved by housing authorities and local government bodies in all states. All Galintel® products are all designed for optimum support of brickwork above clear openings.

Galintel® products undergo independent testing and appraisal ensuring they comply with the requirements of the Building Code of Australia and relevant Australian Standards.

All Galintel® products are guaranteed against defects in materials and workmanship.

Galintel® further warrants that products will suffer no loss of function nor will the adversely affect masonry within 25 years from the date of installation.

We have been proudly partnered with Galintel for over a decade.

Through our strong partnering, Complete Lintels Building Supplies is fortunate to supply 100% Australian made galvanised lintels, delivered on time to your site and at competitive rates.

Choose Complete

Our Range

Stainless Steel Equivalent

High-Quality Steel Lintel Solutions

Galintel is the leading designer, manufacturer, and supplier of high-quality steel lintels products in Australia.

We supply a range of off-the-shelf steel lintel solutions in various standard sizes and lengths that are ready to be dispatched and used in residential and commercial projects across Australia.

We take pride in delivering lintels that meet the requirements of the building and construction industry in Australia.

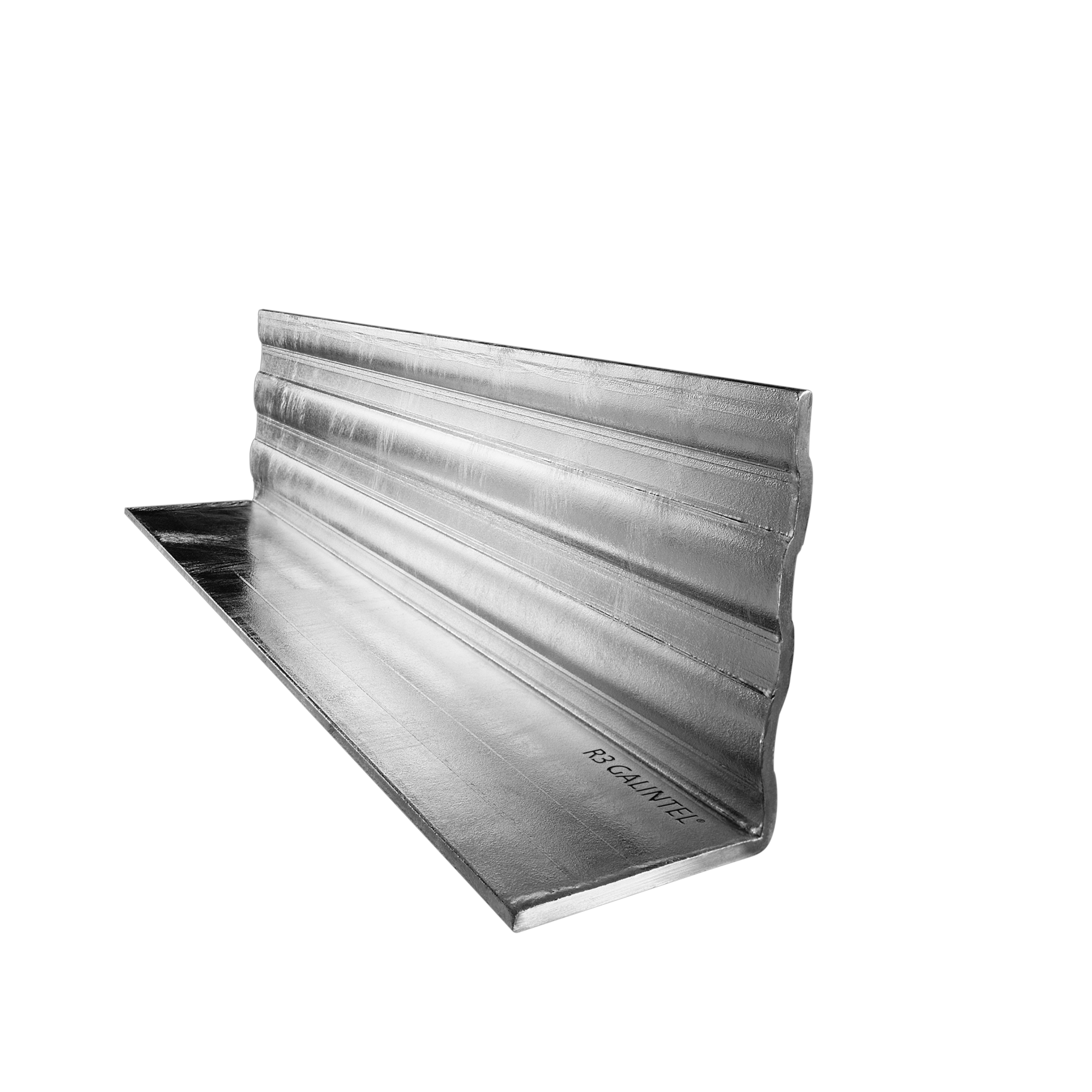

Solid Base Angle

-

Galintel Solid Base Angles have been designed to support brickwork over windows & doors. The brickwork, mortar and lintel work together to form a composite beam with exceptional strength and load-carrying capacity. Genuine Galintel Hot Dip Galvanised lintels are 40% lighter than solid lintels (and 40% easier to carry) with a high strength to weight ratio.

-

The original & unique profile provides a recess for mortar bedding on the vertical leg.

The bonding of mortar, brickwork & steel lintel forms a composite beam of superior strength and load bearing capacity.

40% lighter than conventional steel lintels with a high strength to weight ratio.

Fully Hot Dip Galvanised to AS/NZS4680.

Achieves R3 Durability Rating to AS/NZS2699.3.

Compliant with relevant Australian Building Codes & Australian Standards.

Fully engineered and university tested.

Australian designed and manufactured.

Full product warranty.

Stencilled.

Labelled & bar coded.

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

Rendabar Gen III

-

The next evolution in steel lintels is Rendabar Gen III from Galintel. This Australian Made & designed Rendabar is specifically designed and tested for use in residential builds with cement rendering.

-

ADVANCED DESIGN

The unique ribbed and offset slotted design allows Rendabar Gen III to firmly adhere to mortar and render.

The design echos the trusted Galintel Solid Base Angle for reliable strength and ease of installation.

COMPLIANT & DURABLE

Manufactured and tested in accordance with Australian Standards, Rendabar Gen III complies with the NCC when correctly installed. Hot-dip galvanised in accordance with AS/NZS 4680:2006, it achieves the ‘R3’ durability classification as described in AS 2699.3:2020.

For identification and traceability, it also complies with the stamping and labelling requirements of AS 2699.3:2020 giving homeowners lasting peace of mind.

-

AUSTRALIAN MADE

Proudly made in Galintel’s SO 9001:2015 Quality accredited manufacturing facility in Coffs Harbour, NSW using high quality Australian steel from BlueScope.

MORE BENEFITS

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

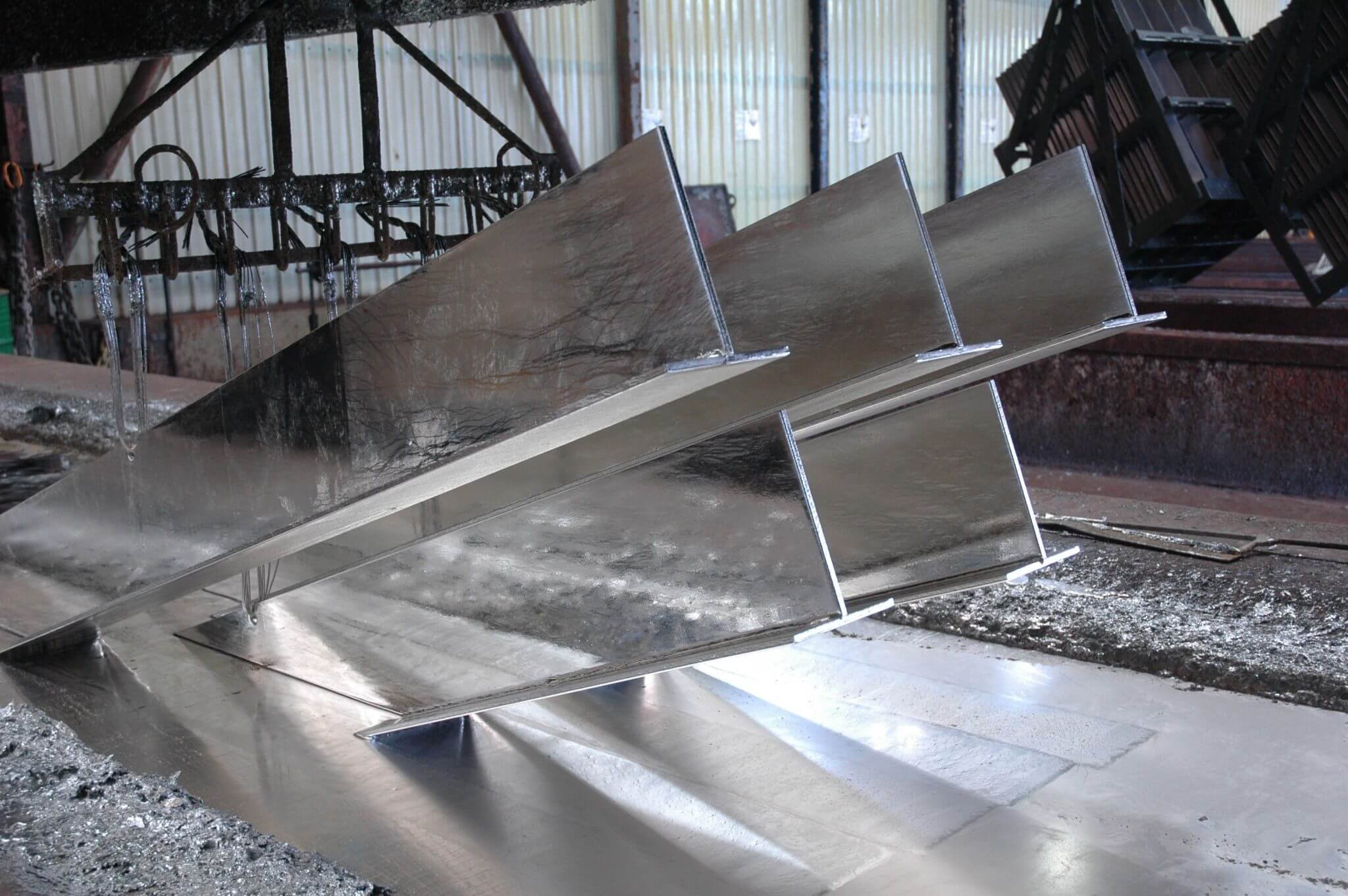

Traditional T-Bar

-

Galintel Traditional T-Bars are fully machine welded structural lintel beam manufactured in Australia using BlueScope steel. They are traditional steel sections used in the support of brickwork over large clear openings and are not reliant on composite action.

-

The original & unique profile provides a recess for mortar bedding on the vertical leg.

The bonding of mortar, brickwork & steel lintel forms a composite beam of superior strength and load bearing capacity.

40% lighter than conventional steel lintels with a high strength to weight ratio.

Fully Hot Dip Galvanised to AS/NZS4680.

Achieves R3 Durability Rating to AS/NZS2699.3.

Compliant with relevant Australian Building Codes & Australian Standards.

Fully engineered and university tested.

Australian designed and manufactured.

Full product warranty.

Stencilled.

Labelled & bar coded.

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

Traditional Steel Angles

-

Galintel Traditional Angles are hot rolled merchant bar lintels manufactured from steel. Traditional steel sections used in the support of brickwork over clear openings are not reliant on composite action.

-

Hot-dip galvanised in accordance with AS/NZS4680

> R3 Durability Rating in accordance with AS/NZS2699.3

> Compliant with relevant Australian Building Codes and

Australian Standards

> Not reliant on composite action

> Hot rolled merchant bar lintel manufactured from steel

> 25 year performance warranty

> Labelled and barcoded

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

Cavi-T-Bar

-

Galintel Cavi-T-Bar is a ideal solution for cavity walls, either double brick or brick veneer with timber. Cavi-T-Bar was developed in response to demand from builders for an economical substitute for built-up steel sections such as parallel flange channel and plate. Similar to a T-Bar but a special top flange incorporated into the upright section, the Galintel Cavi-T-Bar provides an off-the-shelf solution for cavity walls, Hot-Dip Galvanised, fully engineered and University tested.

-

>Convenient, economical substitute for built-up steel sections such as parallel flange channel and plate

>Up to 20% lighter than built-up steel sections

>Unique bulb incorporated into the offset vertical section

>Hot-dip galvanised in accordance with AS/NZS 4680:2006

>R3 Durability Rating classification of AS 2699.3:2020

>Labelled and barcoded

>25 year performance warranty

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

J-Bar

-

Galintel J-Bar shelf beam is the ideal solution for either double brick or brick veneer with timber trusses. The J-Bar was developed as an economical substitute for built-up sections such as parallel flange channel & plate.

Galintel J-Bar is up to 20% lighter than built-up steel sections of equivalent load capacity & with Header & Bottom Flange pre-drilled makes for easy timber fixing & column connection.

-

>Convenient, economical substitute for built-up steel sections such as parallel flange channel and plate.

>Innovative & efficient design.

>Up to 20% lighter than built-up steel sections of equivalent load capacity.

>Off the shelf solution available in a standard range of lengths.

>Fully Hot Dip Galvanised in accordance with AS/NZS4680.

>Achieves R3 Durability Rating in accordance with AS/NZS2699.3.

>Compliant with relevant Australian Building Codes & Australian Standards.

>Fully engineered & university tested.

>Australian Designed & Manufactured.

>Full product warranty.

>Labelled & bar coded.

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

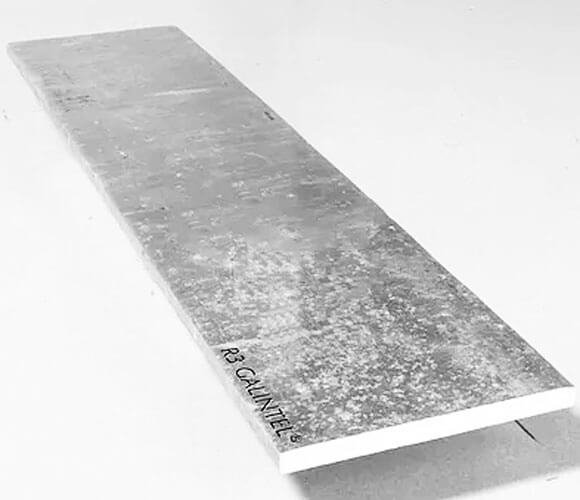

Flat Bar

-

Galintel Traditional Flat Bar Steel is a cost-effective and reliable structural support solution used to support brickwork over clear openings, including windows & doors. They are hot-rolled lintels available in two standard sizes.

At Complete Lintels Building Supplies, we stock a wide range of Flat Bar Steel Lintels in different sizes and lengths. Like all Galintel Steel Lintels, our Traditional Flat Bar Steel product is hot-dip galvanised in accordance with AS/NZS4680:2006 for corrosion protection and quality assured by Galintel.

Flat Bar Steel Lintels are offer a lightweight kg/m ratio making them easy to install for small support work, saving a time on-site.

-

>Fully Hot Dip Galvanised to AS4680:2006.

>Achieves R3 Durability Rating to AS2699.3:2020.

>Compliant with relevant Australian Building Codes & Australian Standards when installed correctly.

>Not reliant on composite action.

>Full product warranty.

>Stencilled.

>Labelled & bar coded.

-

Superior performance

Easy transportation, storage and handling

Long life and durability

Cost effective

Easy identification

Peace of mind

Specifications

R4 Lintels - Solid Angle

Stainless Steel Equivalent - Made for corrosive environments

-

STAINLESS STEEL EQUIVALENT – Made For Corrosive Environments

Galintel duplex-coated R4 steel lintels are built to resist corrosion in severe marine environments.The protective duplex system consists of an R3 hot-dip galvanized base followed by sweep blast cleaning and a paint coating of high-build epoxy with a final layer of acrylic polyurethane.

Galintel duplex-coated steel lintels are specially suited for placement where the atmospheric corrosivity is categorised as ‘C4’ or ‘C5’, which is typically within 1km from a surf coast or 100m from a sheltered bay.

-

Achieves durability class ‘R4’, covering both ‘C4’ and ‘C5’ corrosivity categories for marine exposure.

The R4 duplex coating is equivalent to 316 Stainless Steel – ASTM A240 316L (UNS S31603)

Hot-Dip Galvanised to AS/NZS 4680.

Galvanising overcoated with two protective paint coatings comply with AS 2699.3, durability class ‘R4’.

Fully Hot-Dip Galvanised to AS/NZS4680.

Stenciling to comply with AS 2699.3 requirements for identification marks to be readily visible after installation.

Metal stamped before galvanising for permanent identification.

Labelled & barcoded.

Compliant with the durability requirements of AS 2699.3:2020 (Built-in components for masonry construction), AS 4773.2:2015 (Masonry in small buildings) and AS 3700:2018 (Masonry structures)

Australian designed and manufactured.

Full product warranty^.

-

Ensuring longevity in coastline builds by limiting the effects of corrosion on exposed structural steel lintels.

Can match any architectural needs: Can be paint overcoated on site to colour match building.

Permanently identifiable: steel stamped R4 to ensure lintel is identifiable even if stenciling fades.

Specifications

[Note that the mass for ‘R4’ products will be slightly greater than shown in the tables]

R4 Lintels - T-Bar

Stainless Steel Equivalent - Made for corrosive environments

-

STAINLESS STEEL EQUIVALENT – Made For Corrosive Environments

Galintel duplex-coated R4 steel lintels are built to resist corrosion in severe marine environments.The protective duplex system consists of an R3 hot-dip galvanized base followed by sweep blast cleaning and a paint coating of high-build epoxy with a final layer of acrylic polyurethane.

Galintel duplex-coated steel lintels are specially suited for placement where the atmospheric corrosivity is categorised as ‘C4’ or ‘C5’, which is typically within 1km from a surf coast or 100m from a sheltered bay.

-

Achieves durability class ‘R4’, covering both ‘C4’ and ‘C5’ corrosivity categories for marine exposure.

The R4 duplex coating is equivalent to 316 Stainless Steel – ASTM A240 316L (UNS S31603)

Hot-Dip Galvanised to AS/NZS 4680.

Galvanising overcoated with two protective paint coatings comply with AS 2699.3, durability class ‘R4’.

Fully Hot-Dip Galvanised to AS/NZS4680.

Stenciling to comply with AS 2699.3 requirements for identification marks to be readily visible after installation.

Metal stamped before galvanising for permanent identification.

Labelled & barcoded.

Compliant with the durability requirements of AS 2699.3:2020 (Built-in components for masonry construction), AS 4773.2:2015 (Masonry in small buildings) and AS 3700:2018 (Masonry structures)

Australian designed and manufactured.

Full product warranty^.

-

Ensuring longevity in coastline builds by limiting the effects of corrosion on exposed structural steel lintels.

Can match any architectural needs: Can be paint overcoated on site to colour match building.

Permanently identifiable: steel stamped R4 to ensure lintel is identifiable even if stenciling fades.

Specifications

[Note that the mass for ‘R4’ products will be slightly greater than shown in the tables]

Get in touch.

If you have any queries relating to this product range, please message us today and we will be in touch.